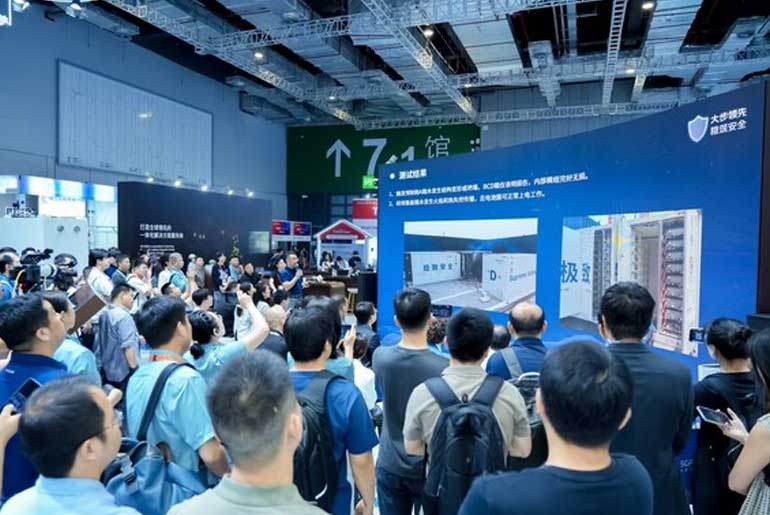

Hithium, a leading global energy storage technology company, held a product safety technology sharing event at the 18th SNEC on June 11, 2025, with the theme “Leading the Future, Forged for Safety.” The company also revealed the full results of the world’s first all-open-door large-scale fire test of its ∞Block 5MWh energy storage system and received certification for the large-scale fire test from international testing authority UL Solutions.

The fire test’s project manager, Hualei Wang, gave a summary of the main points and test history. On-site, a video of the open-door fire test was also played, providing a thorough overview of the test’s methodology, technical features, and outcomes.

Eight battery cells were purposefully heated inside container A to cause thermal runaway, which led to cell-to-cell propagation, starting the open-door fire test. An ignition mechanism ignited the released gases when the battery’s pressure relief vents opened, starting complete combustion while maintaining the container doors open to permit constant oxygen flow. This arrangement gave nearby containers B, C, and D the most heat exposure possible. Four extreme circumstances were used for the test: 100% State of Charge (SOC), complete open-door combustion, dual 15 cm extreme spacing, and disabled fire suppression system.

- Peak Fire Phase: At the fourth hour of testing, the fire reached its peak temperature of 1,372°C. Temperature monitoring confirmed that cell temperatures in all adjacent containers remained well below the cell thermal runaway initiation threshold defined by the UL9540A cell-level test (≤42°C in Container B, ≤80°C in Container C, and ≤70°C in Container D).

- Sustained Combustion Phase: After 15 hours of combustion, the open flame was extinguished. The initiating container remained structurally intact without deformation or collapse. No combustion or thermal runaway propagation occurred in the three adjacent containers. Containers B, C, and D only experienced minor surface damage, while internal battery modules remained completely unaffected.

Hithium’s multi-layered safety design, which extends to the cell, module, and system levels, enabled the test to be completed. High-temperature separators, functional electrolyte additives, and heat-resistant anode/cathode materials increased thermal thresholds at the cell level. Flame-retardant top covers and low-conductivity insulation reduced the probability of spread at the module level. Heat-resistant enclosure materials and a high-strength container frame preserved structural integrity at the system level in the face of intense heat.

At the event, UL Solutions awarded Hithium a certification for the large-scale fire test, recognizing its compliance with UL 9540A and NFPA 855 standards.

Qifeng Xiao, General Manager of the Energy and Automation Division, Asia Pacific at UL Solutions, stated at the certification ceremony, “Hithium’s pioneering open-door extreme fire test was the first to be conducted under full oxygen exposure—far beyond the industry standard closed-door with explosion vent fire test model. The positive outcome not only validated the system’s self-contained fire protection, but also established a valuable reference for the development of global energy storage safety standards through the world’s first open-door fire test.”

Through a completely open testing method, this groundbreaking fire test not only showed Hithium’s excellent technical skills but also its complete confidence in the safety performance of its energy storage devices, providing crucial information and industry best practices. Hithium will keep funding safety innovation, strengthening the “seatbelt” for the world’s shift to renewable energy.