Chungnam National University Researchers have developed a new zinc-bonded polyacrylic acid (ZHP) layer that effectively prevents dendritic growth and stabilizes the anode in zinc-ion batteries. This innovation enhances cycling performance and stability, paving the way for safer and more affordable next-generation zinc-ion batteries.

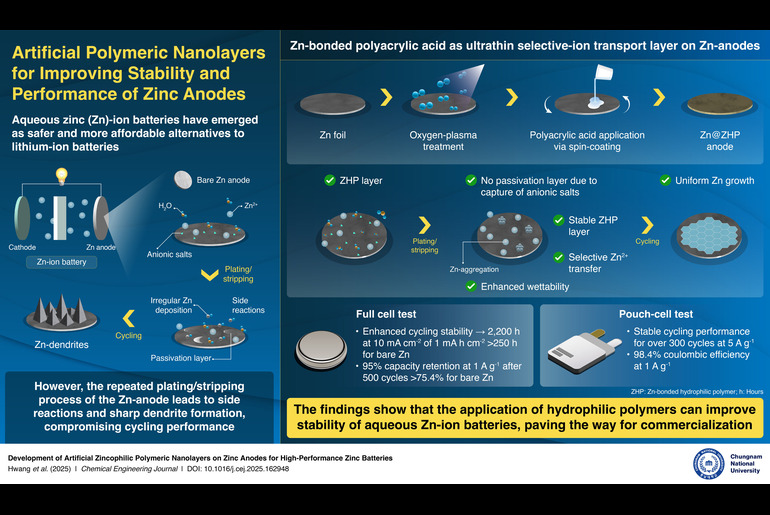

Aqueous zinc-ion batteries (ZIBs) are gaining attention as a safer and more affordable alternative to lithium-ion batteries. Unfortunately, zinc anodes in ZIBs suffer from undesirable side reactions and sharp dendrite formation during charging and discharging, which impacts their cycling performance and stability. Previous attempts to use protective coatings were often too thick or difficult to manufacture, limiting their real-world use.

In a breakthrough, a research team led by Associate Professor Woo-Jin Song from the Department of Organic Materials Engineering at Chungnam National University, South Korea, designed a new ultra-thin selective-ion transport layers (SITL) that is both effective and easy to produce.

“In this study, we developed a nanoscale zinc-bonded polyacrylic acid (Zn–PAA) protective layer for zinc anodes via oxygen plasma treatment,” explains Dr. Song. “Unlike conventional thick and complex coatings, our approach offers a simpler fabrication process and is scalable for large-area applications.”

Their study was made available online on May 8, 2025, and published in Volume 515 of the Chemical Engineering Journal on July 1, 2025.

This new SITL is based on polyacrylic acid (PAA), which can prevent direct contact between the zinc anode and water-based electrolyte, inhibiting corrosion. This significantly reduces dendritic growth, stabilizing the anode interface. Thanks to its hydrophilicity, it also improves ion transfer between the electrolytes and the anode, promoting uniform distribution of zinc-ions and enhancing battery performance.

However, bare PAA tends to dissolve in water-based electrolytes, reducing cycling performance. To prevent this, the researchers applied oxygen plasma treatment to zinc-anode, which enhanced adhesion between PAA the layer and the anode surface. The PAA was deposited on the treated zinc-anode using the cost-effective and scalable spin-coating technique, resulting in a nanoscale PAA coating. The PAA-coated anode was then heated on a hot plate, forming the zinc-bonded PAA (ZHP) layer.

The ZHP coated zinc anode demonstrated remarkable performance. In full cells, it retained 95% of its capacity after 500 cycles. In pouch cells, the anode demonstrated stable cycling for over 300 cycles.

“The enhanced stability of water-based electrolytes makes ZHP based ZIBs ideal for safety-critical industries such as grid-scale energy-storage systems and detection sensors.” remarks Dr. Song. “And due to their low cost and toxicity, these batteries are also well-suited for portable electronics and wearables.”