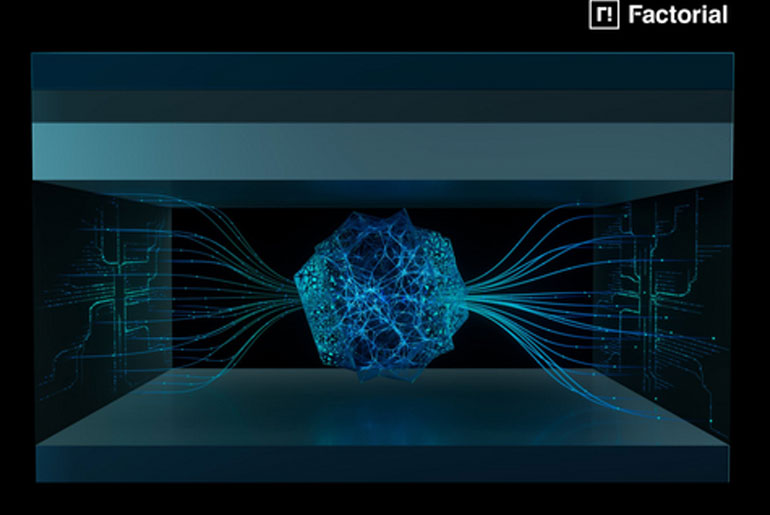

A pioneer in solid-state battery technology, Factorial Inc., recently unveiled Gammatron™, a unique AI-driven simulation platform that will speed up the creation of next-generation batteries by enhancing the methods for predicting, validating, and optimizing battery performance.

Gammatron™ was developed as a necessity-driven solution to alleviate significant delays in battery development, drawing on Factorial’s own R&D experience. Gammatron™ combines electrochemistry, thermodynamics, and high-fidelity lab data to simulate and optimize battery behavior at the material and cell-system levels, in contrast to standard AI systems that only concentrate on system-level modeling.

“Validating a new cell design can take years, but with Gammatron™, we’ve demonstrated that we can dramatically shorten that timeline—forecasting long-term performance from just two weeks of early testing, instead of the typical three to six months,” stated Siyu Huang, CEO of Factorial. “By combining automation with data-driven insights, we’re accelerating development with greater speed and control.”

Key capabilities of Gammatron™ include:

- AI-driven digital twin for battery cells that accurately delivers cell state of health predictions, and accelerates fast charging optimization that maximizes capacity, minimizes degradation and internal stress, while ensuring battery safety and longevity.

- Accelerating electrolyte formulation using molecular modeling and machine learning to engineer compositions for specific performance targets based on a deep understanding of molecular interactions.

- Advanced physics-based modeling to simulate internal battery behavior, including stress, heat, and degradation, that can’t be directly observed in testing.

GammatronTM, which Factorial and Stellantis developed together, assisted in predicting battery performance prior to the completion of full tests, which was crucial in moving the validation program ahead of time. In many instances, cycle life has been doubled without changing cell chemistry thanks to GammatronTM-enabled protocol adjustment.

“Batteries are complex dynamic chemical systems. Gammatron™ combines machine learning with scientific feature engineering. Where most platforms hit a wall with shallow machine learning, Gammatron™ goes deeper and shows engineers which material and design changes will unlock longer life and higher performance,” stated Raimund Koerver, VP of Business Development at Factorial. “It’s not just about predicting outcomes – it’s about enabling better ones.”

This technology, which was created to support Factorial’s primary emphasis on next-generation battery cells, is essential for expediting internal development, improving overall cell performance, and simplifying customer qualifying. It facilitates more effective, data-driven innovation across the battery lifecycle by including cutting-edge features like material screening, battery cell digital twins, and cell manufacturing traceability.

When GammatronTM first launches, it will be a tech-enabled service that is run internally for co-development with a few chosen partners. Both classic lithium-ion programs and solid-state battery development can use the platform.

Factorial’s partnership with Stellantis will include a demonstration of Gammatron™ at the May MOVE London conference.