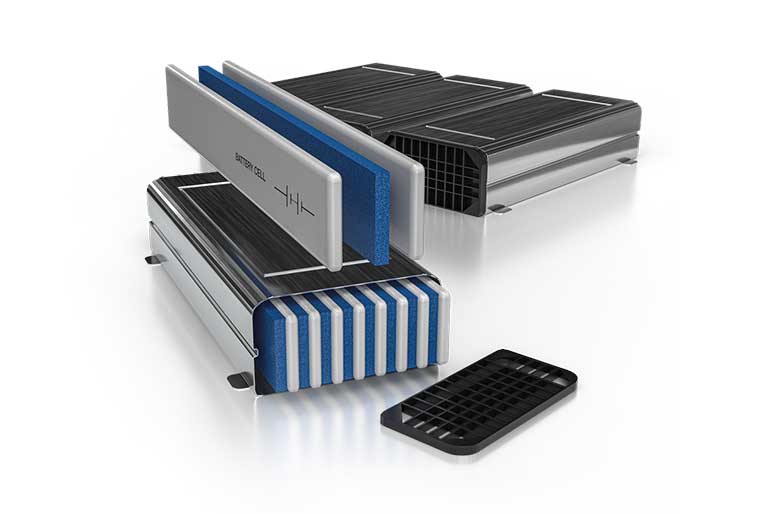

Zotefoams ECOZOTE PP, ZOTEK T, and Plastazote LD FR provide a range of benefits for battery packs that include temperature regulation and impact and vibration protection, which contribute towards maximizing the lifecycle of the battery.

The Zotefoams ECOZOTE PP (polypropylene) range features sustainable recyclable foams that are lightweight and flame-retardant with low thermal conductivity. The materials also have high rigidity and strength, plus a desirable compression curve, making them well suited for use as cell dividers or general gap fillers for battery packs.

“Our PP foams are the latest addition to the Zotefoams extensive materials portfolio. They are low-thermal conductivity materials that are ideal for regulating the temperature of battery packs.”

– Sam Norman, Zotefoams Head of Business Development—Transport & Smart Technologies.

“The materials are also recyclable, so they meet the requirements of OEMs who want the flexibility of materials that are functional and sustainable at the same time. Our PP range delivers on cushioning and impact protection to prevent batteries from damage caused by vibration or impact, while allowing for cell expansion and contraction when the batteries are charging.”

“Our PP foams are the latest addition to the Zotefoams extensive materials portfolio. They are low-thermal conductivity materials that are ideal for regulating the temperature of battery packs.”

-Sam Norman, Zotefoams Head of Business Development—Transport & Smart Technologies.

ZOTEK T ultra-light closed-cell, crosslinked foams have excellent compression properties and resilience. ZOTEK T is also an ideal material for use in cell divider applications due to its excellent compression performance.

Plastazote LD FR materials are lightweight, fire-retardant foams that offer thermal insulation and cushioning for battery pack assemblies.

“We are constantly developing and updating our product offering—innovation is at the heart of everything we do at Zotefoams. We are working with some key players in the battery sector to develop a portfolio of materials to meet specific project requirements.”

“Our unique manufacturing capabilities mean we are ideally positioned to work closely with our customers to develop cutting-edge solutions for their specific requirements.”

– Sam Norman, Zotefoams Head of Business Development—Transport & Smart Technologies.

Zotefoams’ unique chemical-blowing-agent-free 3-stage manufacturing process ensures that foams are consistent, durable, and can be customized to suit a variety of applications.

High-performance closed-cell crosslinked foams are formed using temperature, pressure, and nitrogen borrowed from the atmosphere. The combination of foaming process and polymer performance delivers excellent fire resistance, high-temperature stability, toughness, and insulation. An international business with manufacturing facilities and commercial operations in the UK, Europe, North America, and Asia.