As the global automotive industry accelerates toward electrification, the demand for safer, lighter, and more efficient battery pack solutions is intensifying. Covestro, a pioneer in polyurethane (PU) technologies, has developed a suite of advanced PU-based materials tailored for electric vehicle battery packs (EVBP). These include Baypreg® STM, Baydur® HP-RTM and Baysafe® BEF, each engineered to address specific structural, thermal, and safety challenges in EV applications.

This article explores the technical merits, processing advantages, and application potential of these three flagship solutions, highlighting how they contribute to the next generation of electric mobility.

Baypreg® STM: Lightweight Composite Battery Covers

Baypreg® STM is Covestro’s innovative polyurethane system designed for high-performance EV battery covers and structural components in electric vehicles, offering a sustainable alternative to traditional materials.

The manufacturing process utilizes advanced Spray-Transfer-Molding technology, where robots precisely spray PU formulation onto glass fiber mats. These mats are then transferred into a compression mold where the composite part is formed and cures under controlled pressure and temperature conditions.

The process delivers significant manufacturing advantages: short cycle time, high automation potential, efficient material usage, and the integration of flanges for mounting on the battery casing. Additional functional material layers and thin steel sheets can be integrated into the composite structure during the compression step, if required.

The final components outperform traditional solutions with up to 60% weight reduction compared to steel, while providing high mechanical properties and excellent flame retardancy to increase fire protection in case of a thermal event. Additional benefits include electrical insulation, a part smooth surface, gas impermeability and corrosion resistance – making Baypreg® STM ideal for modern EV applications.

For vehicle underbody protection, Baypreg® STM offers a unique sandwich design combining our proven Spray-Transfer-Molding technology with a rigid polyurethane foam core. The efficient process allows manufacturers to create strong, lightweight panels featuring acoustic properties, durability and impact resistance, protecting the battery pack against stone chipping and ground impact loads. The resulting components provide comprehensive vehicle protection with integrated functionality for modern mobility solutions.

Key benefits

- Weight Savings: Up to 60% lighter than steel solutions, improving EV range and efficiency

- Safety First: Excellent Flame retardancy to shield & protect against fire

- Efficient Production: Short cycle times and high automation enable efficient, cost-effective manufacturing

- High Strength: Superior mechanical properties while maintaining significant weight reduction

- Protection: Comprehensive shielding against impacts, stones, and environmental factors

- Design freedom: Integration of mounting flanges and functional layers in a single production step

- Baydur® HP-RTM: High-Performance Composite Top Covers

Overview

Baydur® HP-RTM is a polyurethane composite solution designed for battery top covers using the High-Pressure Resin Transfer Molding (HP-RTM) process. It offers a compelling combination of flame retardancy, mechanical strength, lightweight design, and production efficiency.

The technology combines high-pressure injection of polyurethane resin systems with glass fiber reinforcement to create lightweight yet extremely strong components. The HP-RTM process involves injecting the resin mixture into a closed mold containing pre-positioned fiber reinforcement under high pressure, allowing for rapid filling and curing.

Material Performance

Baydur® HP-RTM meets the stringent UL94 V-0 flame retardant standard at minimal thickness. It also complies with REACH, RoHS, and GB38031-2020 standards, covering vibration, shock, collision, extrusion, thermal cycling, and insulation performance.

Components manufactured using Baydur HP-RTM exhibit exceptional mechanical properties and outstanding strength-to-weight ratio. The high impact resistance and excellent dimensional stability make it ideal for EV battery applications where structural integrity is paramount.

Lightweight Advantage

Baydur® HP-RTM offers around 60% weight savings compared to steel used in battery enclosures. This reduction directly contributes to improved vehicle range and energy efficiency – a critical factor in EV performance and consumer acceptance.

The combination of glass fiber reinforcement with Covestro’s specialized polyurethane resin systems creates parts that are substantially lighter than comparable metal components while maintaining the required structural performance.

Process Efficiency

The HP-RTM process enables automated fiber layering, vacuum-assisted resin injection, and rapid curing, resulting in high throughput and consistent quality.

This streamlined production supports mass manufacturing with minimal waste and high repeatability, making it suitable for the increasing production volumes required by the growing EV market.

Baysafe® BEF: Encapsulation Foam for Cell Protection

Overview

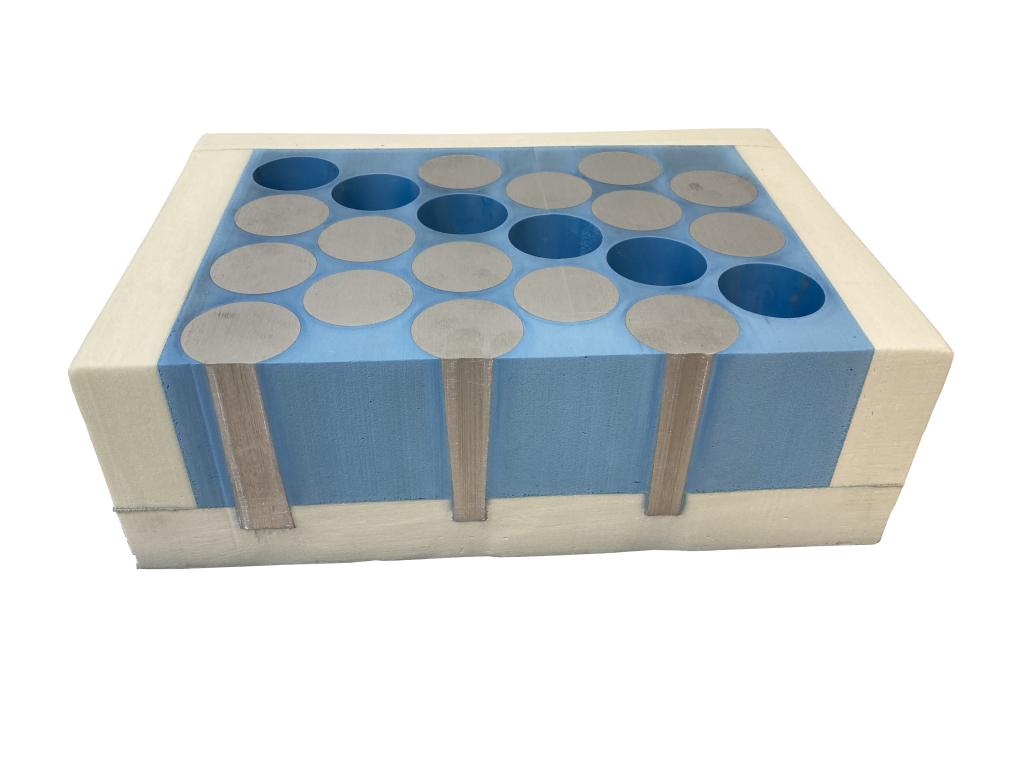

Baysafe® BEF is a two-component PU encapsulation foam designed for thermal insulation and mechanical protection of individual battery cells. It is available in semi-hard and hard foam variants, customizable to specific battery layouts and performance requirements.

This specialized polyurethane foam system is engineered to provide controlled deformation and energy absorption during impact events, making it ideal for protecting sensitive battery cells. The Baysafe BEF technology allows for precise control of foam density, cell structure, and mechanical properties, enabling engineers to design components with tailored energy absorption characteristics.

Material Performance

Compared to silicone-based solutions, Baysafe® BEF offers lower cost, higher mechanical strength, improved thermal insulation, and reduced thermal runaway risk – a critical safety consideration in EV battery design.

The engineered nature of these foams allows for optimization of the material structure to achieve maximum energy absorption with minimum weight. This is particularly important in EV applications where every gram of weight saved contributes to extended vehicle range.

Customization and Processing

Baysafe® BEF formulations are tailored to customer needs, offering adjustable viscosity for wide processing windows, excellent cell bonding strength, and isolation of heat conduction between cells.

The encapsulation process involves pre-installation and pre-heating of cells, high-pressure injection molding, and curing. This ensures robust encapsulation with minimal voids and optimal thermal management, contributing to both battery performance and safety.

Sustainability Considerations

Sustainability has become increasingly important in materials selection, and Covestro’s polyurethane technologies offer several environmental advantages. The weight reduction achieved through these materials leads to lower energy consumption and extended range in electric vehicles, improving their overall environmental footprint.

Manufacturing processes for these materials typically consume less energy than traditional methods like metal stamping or injection molding. Additionally, Covestro is exploring the potential for incorporating recycled content in certain applications and researching bio-based raw materials for future formulations.

The company continues to invest in research and development to further improve the sustainability profile of these materials, including work on recycling technologies and bio-based alternatives. This commitment aligns with the broader sustainability goals of the EV industry.

Baypreg STM, Baydur HP-RTM and Baysafe BEF represent cutting-edge polyurethane technologies that are transforming EV battery pack design and manufacturing. By offering exceptional performance, manufacturing efficiency, and sustainability benefits, these materials are helping manufacturers meet the challenges of modern electric vehicle design.

As the transportation industry continues to evolve toward electrification and greater sustainability, these advanced material solutions will play an increasingly important role in enabling the next generation of vehicles that are lighter, safer, more efficient, and more environmentally friendly.

The combination of lightweight construction, excellent mechanical properties, efficient manufacturing processes, and customization potential makes these polyurethane technologies a compelling choice for EV manufacturers seeking to optimize their battery systems. As production volumes increase and cost pressures intensify, the advantages of these materials will become even more significant, potentially establishing them as the standard solution for EV battery protection systems.